Now that you have learned what an industrial ceramic polish machine can do and how it works – the basic three polishing steps, you can choose the right specifications. It’s not only the daily output of the machine you need to consider but also some crucial points below.

1. What’s Your Rim’s Condition and Design When They Arrive?

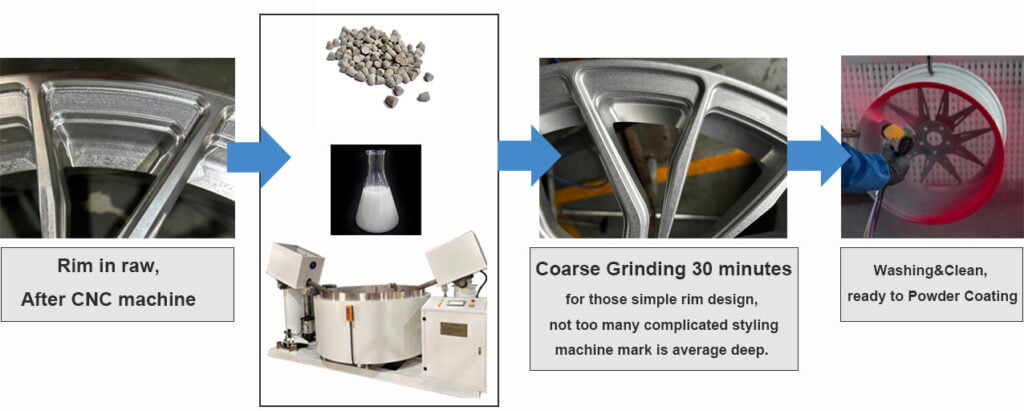

There are deep machining marks for rims just coming off the CNC machine, so step #1 coarse grinding is necessary.

If the rim arrives in good condition, some deep machining marks are already hand polished removed, and the rim styling is simple. You can start from Step #2 medium polishing, using smaller ceramic balls.

2. Color Powder Coating or Polished Finishing?

For painted or diamond-cut wheels, after step #1 coarse grinding for 10-30mins, it’s ready to be painted, coarse grinding works on forged and cast wheels, it can save a lot of time and meanwhile take the standards to a higher level, as they’re not only work on the surface but also the sides too.

For polished finishing, below are the steps and a video for your reference, we will customize the stages for your plants after we learn about your wheels.

This is only a guideline and the duration of the finishing process may depend on the initial condition of the wheels.

3. Quantity of the Machine?

We don’t suggest clients change the ceramic balls while using them cause it will be wasting of time. We advise the most efficient way is to keep one kind of media in the polishing machine, it will be simple to operate, you just need to load the rims and press start on the screen.

Below are some details of the machine for your reference:

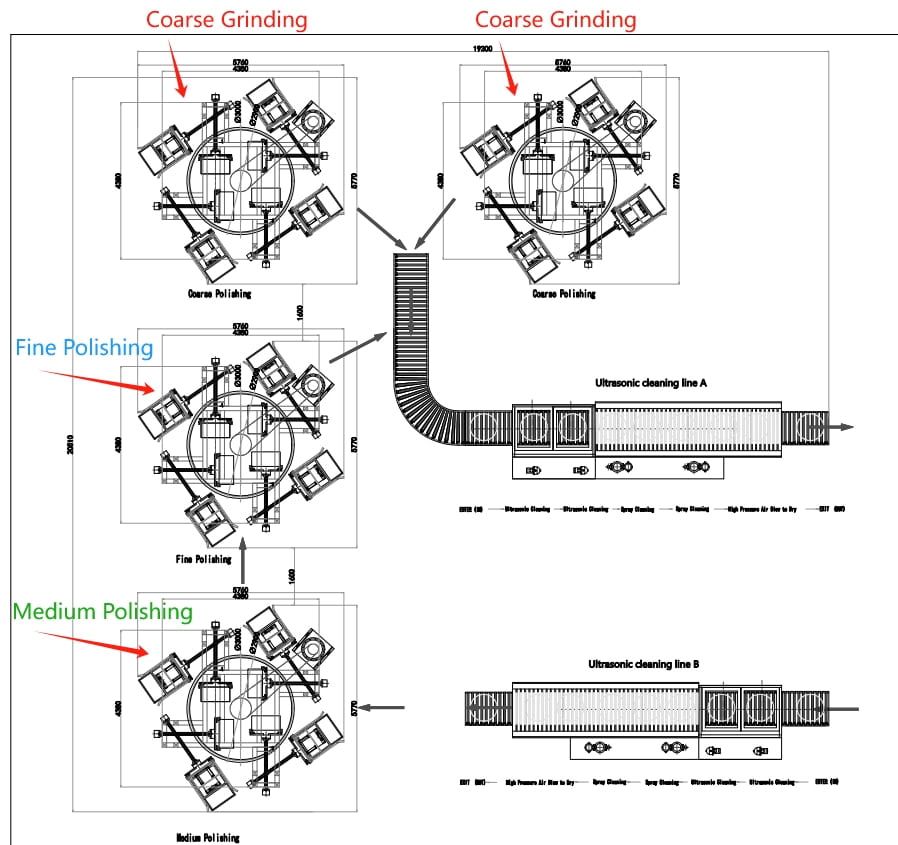

In this case, as stage #1 coarse polishing is the most time-consuming stage, if we want the workflow to go smoothly, then this machine quantity should be more than the other steps. see below the solution we made for clients.

Workflow #1 For Rims in Raw:

Coarse Grinding – Ultrasonic cleaning line A – Medium Polishing – Fine Polishing – Ultrasonic cleaning line A

Workflow #2 For Rims pre-polished :

Ultrasonic cleaning line B – Medium Polishing – Fine Polishing – Ultrasonic cleaning line A

This workflow will help you save production costs by at least 40%, with the least carrying work and a clean polishing workplace.

If you still have concerns about deciding the best solution please feel free to contact us, our experiences will help you find the most economical and thoughtful solutions and the most suitable rim polishing machine for better running a workshop.