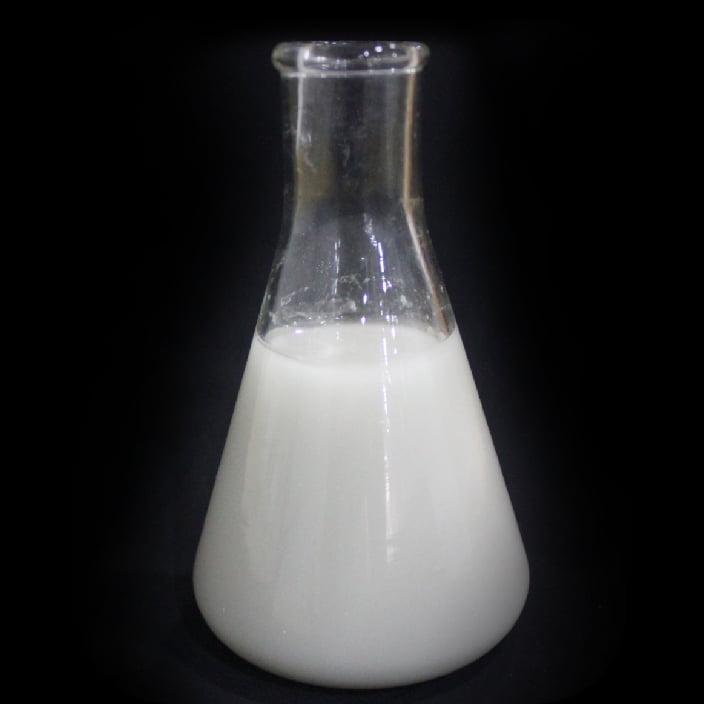

We develop, test and continuously improve the formulation of our liquid, powder, and paste compounds at our facility in Shenzhen, China. This is also the place where we manufacture our compounds. All Huaqing compounds are environmentally friendly and are formulated for our high energy-polishing machine.