Two Station Rotary Grinding & Polishing Machines for cars have the same function as a single station machine but allow 2 rims polishing simultaneously, saving production time and workspace while improving daily output.

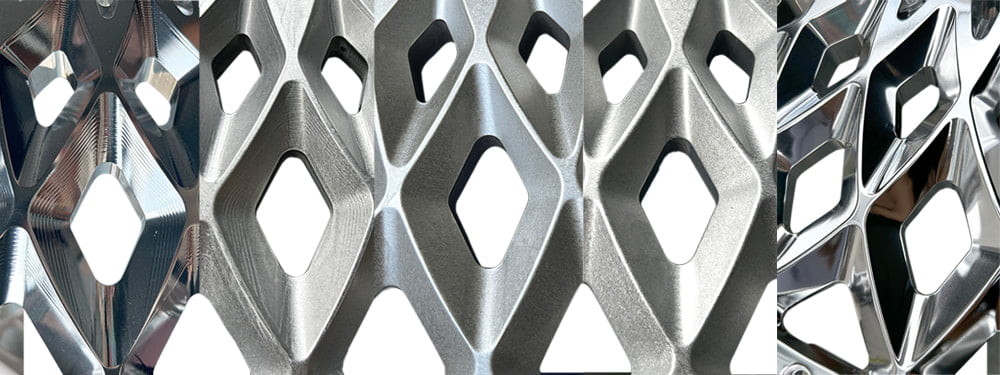

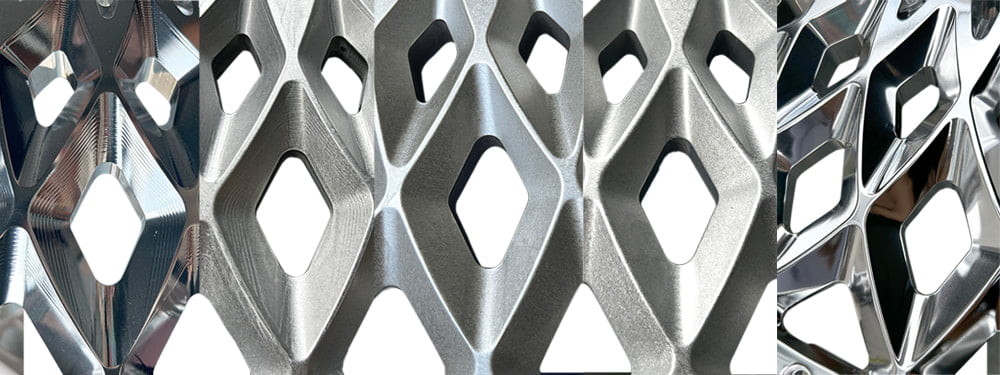

From Raw to Polished Wheels

1️⃣ Remove CNC Marks: Machine grinding eliminates machining traces for a smoother surface.

2️⃣ Sanding with 800 Grit: Prepares the surface for polishing by creating an even texture.

3️⃣ Machine Polishing: In just 15 minutes, our machine achieves a bright, mirror-like finish—every time!

Why Choose Us?

💡 Compatible with rims up to 32 inches, forged or cast.

🛠️ Low maintenance, high durability.

⏱️ Save over 60% in manpower and reduce polishing time.

🌟 Dust-free, spark-free, and safer for operators.

🚛 Brighter and more consistent finish compared to traditional methods.

Machine polished rims performance:

httpv://www.youtube.com/watch?v=2Fs4Pc0P610

How Our Expertise Benefits Your Polishing Process

At our company, we live and breathe ceramic polishing every single day. Our deep immersion in the craft ensures that we understand the intricate details of setting up and optimizing your polishing machine. This level of hands-on experience directly translates to a superior product for our clients.

Key Benefits:

- Precision Setup

We are meticulous in calibrating our machines for various rims, including wheels and other critical parts. This means less trial and error on your end, saving valuable time and resources.

- Proven Processes

Over years of daily usage, we have fine-tuned our methods to be exceptionally efficient. Our established procedures are designed to ensure maximum performance and minimal downtime.

- Enhanced Reliability

Unlike manufacturers who only design but never use their machines, our continuous usage guarantees that you receive a product that is not just theoretically sound but practically effective.

- Knowledge Transfer

By applying our extensive know-how, we provide detailed guidance and support. This helps you quickly understand and utilize the machine’s full potential.

Why This Matters

When you choose our polishing machines, you’re not just buying equipment; you’re investing in a system backed by unparalleled experience. The end result is a highly reliable, efficient, and user-friendly machine that delivers consistent, high-quality results.

- Boost productivity while lower production costs.

- Offer customized facility design and polishing solution guide at start and ramping.

- Daily output quality and quantity guarantee and work environment upgrade.

- Lightning response of consumables delivery and after-sales maintenance

- Rotation Barrel diameter 8 feet (2400mm) to ensure better polishing effect, and available for rim size up to 32”.

Pros of Machine Polishing:

#1. Cost and time-saving. Reduce manpower by at least 60%.

#2. Clean & friendly working site. Do not produce any aluminum powder or noise.

#3. Easy to operate and low maintenance. Quality is stable without skilled workers.

#4. Compatible with various rims. size from 16″-32″.

Check our social media to see more relevant videos:

-

-

-