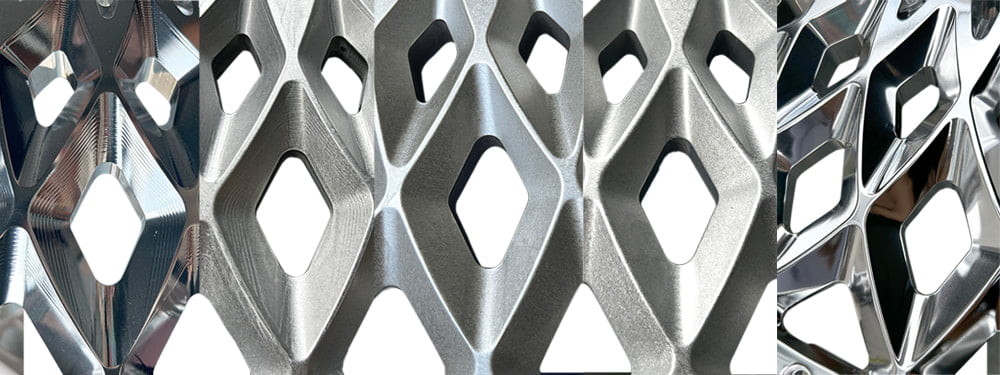

This Machine is designed to polish a car/truck’s rims, it’s aim is to replace the whole hand polishing process by only using a machine.

The basic principle is to use ceramic balls with special compounds to grind the rims repeatedly, after using different balls to polish 2 or 3 times, the rim can be shiny and bright as requested.