One is a one-station ceramic polishing machine, the best choice for after-sales rim repair, refit, or customized shops.

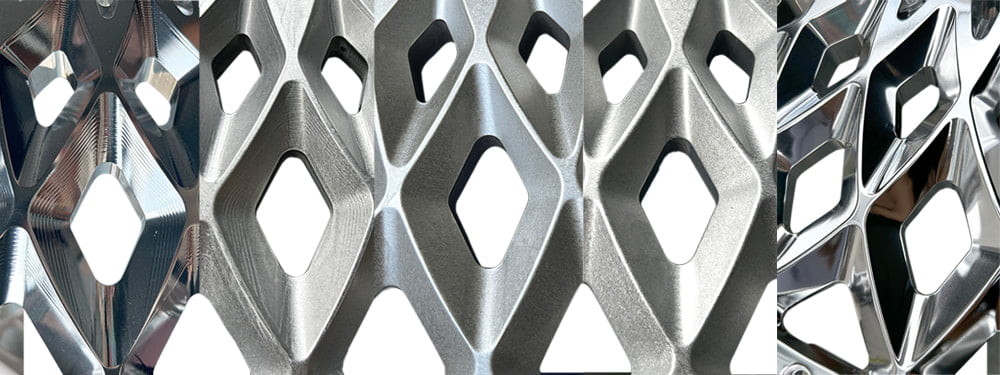

We are the manufacturer of vehicle rim polishing machinery, which is specially designed to polish, debur or refurbish car rims. Using ceramic tumbling media with an automatic rotary robot arm, rims can be made into a shiny, mirror-like surface without manual polishing. The application includes alumina alloy and stainless steel, motorcycle, car, and huge truck wheels.