- Built to remove CNC marks and deburr with precision.

- 800# girt to polishing wheel takes 15 minutes per wheel.

- Modiify premier to a rough surface before color painting.

- Adjustable cycle time to suit different wheel surfaces.

- Retouch the first layer of electroplating rims in 15 minutes.

- Compatible Variety, works for different rim sizes.

- Efficiency, reduce most of the hand polishing steps.

- Both forged and casted wheels can be processed.

- Clean working site. Powder-free while operating.

- Low maintenance and durable.

- Faster, Brighter, Cleaner!

Polishing Stages

HuaQing Technology have developed in partnership with major manufacturers in the globle automotive industry, a high quality, repeatable finishing solution to achieve a highly polished finish within the most eco-friendly, cost-effective methods.

Wheel After Machined

Wheel After Abrasive Grinding

Polished By15 Minutes

Enhanced Mirror Liked

Massive Wheel Polishing Equipment

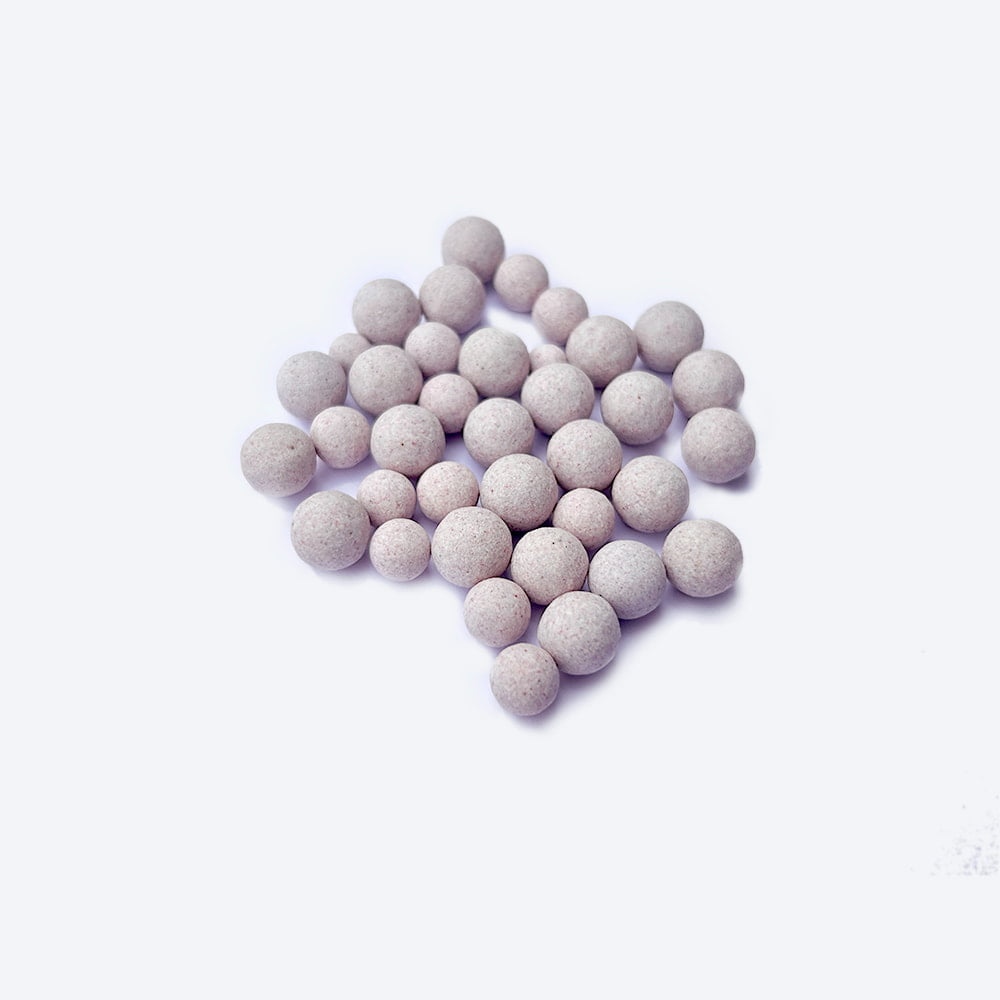

Compound & Media Is Vital For Polishing Performance

The media and chemical compound is added to the machine, along with the wheels, and the machine is set to run for a specified amount of time, allowing the media to rub against the surface of the wheels, resulting in a smooth, polished finish.

Customer Case

Some of the onsite images from customers, we guarantee 100% coustomer satisfaction, 100% quality test before equipment ship out to clients, and onsite installation and training service provided.

Frequently Asked Question

Depends on your initial condition of rims and your request of daily output. one site machine is normally for after sales refurnish, 2-4 stations are for rim manufacturers.

Yes, our machine can polish from rim in raw to a mirror bright surface.

Yes, we do. We manage production of the ceramic balls and compound in house.

Yes, so far we shipped to Southest Asia, Turkey, USA, Mexico...

One year warranty of the machines, and technical support for enternal.

It depends on the size and quantity you need, we can advise the best solution for your option once we learn more about you.