Choosing the right polishing media depends on various factors such as the material of the wheel, the desired finish, and the specific requirements of your polishing process. Here are some key considerations.

Compounds and sizes categorize ceramic polishing media, we have ceramic, polyester, resin, zirconia, aluminum oxide, etc. These compounds were tested with the best mixings with each other to achieve the best polishing effects.

Our ceramic media comes in various abrasive grades, they are suitable for various deburring, radiusing, and polishing processes, and are specially formulated to go hand-in-hand with compounds. Our ceramic media has a high strength and long wear-ability too.

A polishing media to remove machining marks?

Pre-Polish: Use coarser media for the initial stages to remove larger imperfections.

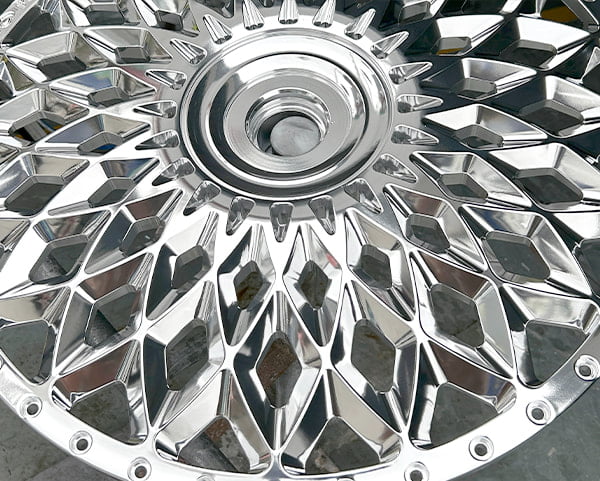

If you are trying to remove CNC machining marks from a raw rim, then the below polishing media we created is the best solution cause it has the best cutting force, and the curve of the media just works great with the rim designs, not easy to stuck and stick on the rims.

Not only this abrasive polishing tumbler media is good at removing machining marks, but also can remove dirt and scratches in a very short time, estimated within 20 minutes of grinding with our compounds. What’s more? rims can go directly to power coating, after cleaning this media polishing.

Cast Rims’ After Coarse Polishing By Rotary Ceramic Polishing Machine

Compounds are integral to the success of a polishing process. They can help to suspend the dirt, oils, and media residues and flush them from the system, as well as keep the components and media clean. Other advantages include corrosion inhibition, brightening of different materials, and removing scale post-heat treatment. As the compound acts as a lubricant, it extends the media life.

A media to polish a mirror-like finishing surface?

Final Polish: Use finer media to achieve a high-gloss, smooth finish.

If your rims are pre-hand-polished by #800 or #1000 sandpaper, trying to find a machine to polish to a chrome surface, or you want to refurbish polishing rims, then this 3*3mm size media is the one you’re looking for. With less cutting force but more brightening effects, after grinding together with our compounds, you will have an amazing shining performance within a coffee break.

Media Consumption :

- Consider the longevity and consumption rate of the media to ensure cost-effectiveness and consistent performance.

By evaluating these factors, you can select the polishing media that best suits your specific needs and achieves optimal results for your polishing operations.

More info