To achieve the best results in Ceramic Wheel Polish Machine polishing, we will use ceramic balls and compounds to grind together in the center barrel. For a mirror-like surface rim through machine polishing, follow these essential steps:

let’s have a quick tour of the steps below:

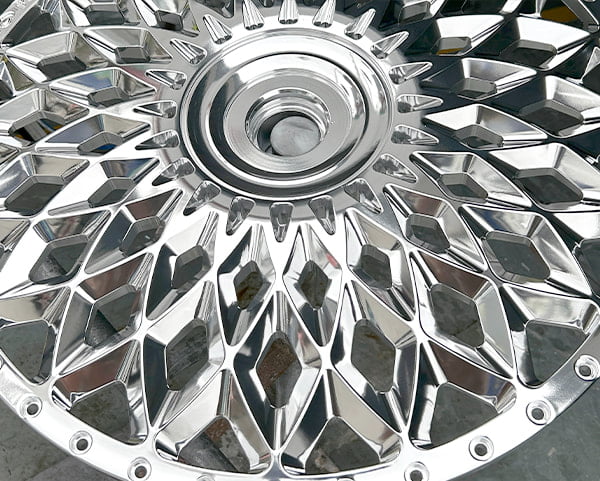

Rim Surface Condition: After CNC Lathing

Our ideal is to replace the whole rim hand-polishing process with just a machine, this repeated tiresome work which takes long working hours should be done by machine to save a lot of production cost and capacity.

Step 1 Coarse Grinding: Remove Machining Marks

Wheels go through the grinding process using media 6*6mm which is a concentrated cleaner and polishing compound. Depending on the initial condition of the surface the process time can take between 10 minutes to 40 minutes.

It can clean the rim thoroughly to remove any dirt, grease, or debris.

we can also call it Initial Grinding: Use ceramic balls and appropriate compounds to begin the coarse grinding process. This step smooths out any imperfections and prepares the surface for finer polishing.

Step 2 Smoothing Surface: Smoothing Before Final Polish

After the surface has been cut down it needs to be smoothened and prepared for the polishing stage. This is achieved using a finer ceramic to further refine the surface, We can call it Intermediate or Medium Polishing: The time needed to carry out this process can vary from 15 to 20 minutes.

Step 4 Mirror-Like Polishing

The final stage uses the finest ceramic balls and compound to grind with the rims. The process time only takes about 10 minutes. The smoother surface of the rims you got on previous steps, the brighter and shinner looks.

Let’s see a wheel polishing process only by our machine:

Forged Rim:

Cast Rim: